What gribbles could do for us

They are best known for their destructive properties, but a tiny marine worm’s eating habits could help fuel the cars of the future.

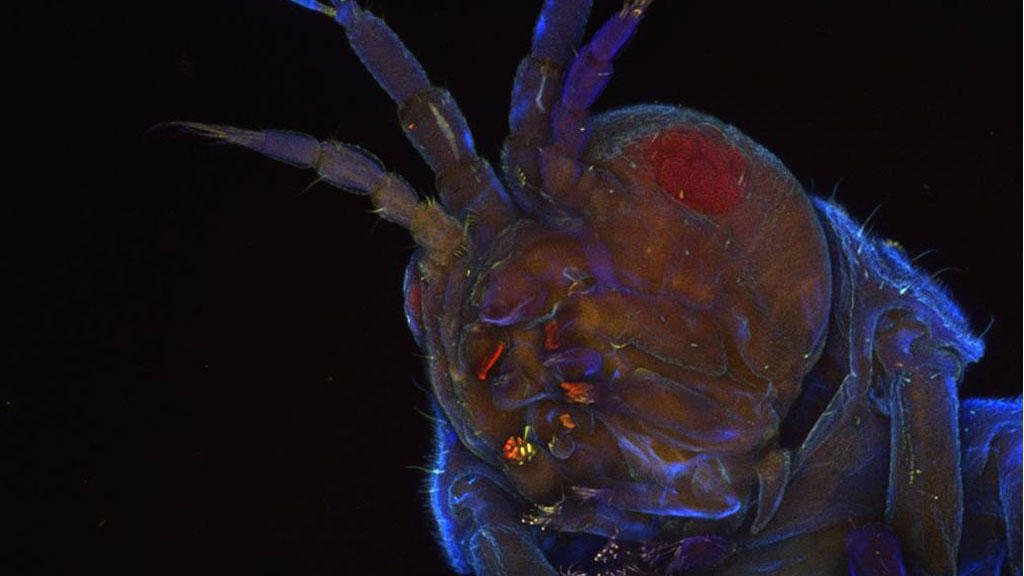

Gribbles wreak havoc in coastal communities by feeding on the wood of seaside piers. Scientists have identified a key enzyme in their gut which is highly acidic, extremely resistant and has the ability to break down wood.

This latest discovery could lead to sustainable liquid biofuels by manufacturing these enzymes on an industrial scale.

To create liquid fuel from woody biomass, such as wood and straw, the polysaccharides (sugar polymers) that make up the bulk of the materials must be broken down into simple sugars that are then fermented to produce liquid biofuels.

Using advanced biochemical analysis and X-ray imaging techniques, scientists at York and Portsmouth universities have determined the structure and function of this enzyme.

Simon McQueen-Mason, professor at the University of York, said: “Enzymes are proteins that serve as catalysts, in this case one that degrades cellulose.

“By studying the structure of the enzyme we have found a number of unusual features that could be of benefit to the biofuels industry.”

Rather than trying to get the cellulase (an enzyme that converts cellulose into glucose) from gribbles, the team has transferred the genetic blueprint of the enzyme to an industrial microbe that can produce it in large quantities, in the same way that enzymes for biological washing detergents are made.

Cost effective

Making biofuels is currently too expensive. But by re-creating the gribble enzyme on an industrial scale it is thought this process could also become more cost effective.

Professor McQueen-Mason added: “The robust nature of the enzymes makes it compatible for use in conjunction with sea water, which would lower the costs of processing.

“Lowering the cost of enzymes is seen as critical for making biofuels from woody materials cost effective. Its robustness would also give the enzymes a longer working life and allow it to be recovered and re-used during processing.”

The research has been funded through the Biotechnology and Biological Sciences Research Council.